Related Resources

Browse our technical library of resources, including; white papers, product brochures, technical datasheets, webinars, and more.

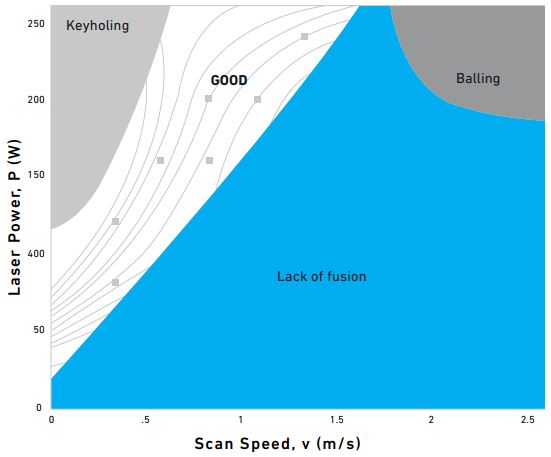

Carpenter Technology and their branch of 3D printing experts, Carpenter Additive, carried out a study to create a systematic framework to optimize additive manufacturing for Nitinol, focusing on three factors for success:

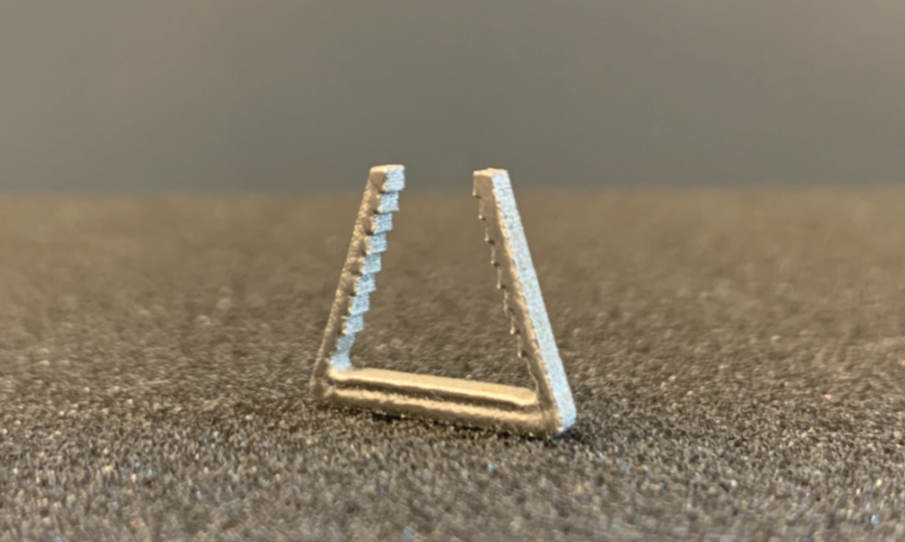

Download the complete report for results on the samples printed to demonstrate the shape memory effect in a 3D printed Nitinol component.

Combining more than a hundred years of metallurgical leadership with unrivaled knowledge of additive manufacturing technologies, Carpenter Additive is committed to helping customers solve material and process challenges. Developing end-to-end solutions to add consistency, reduce risk, and continuously improve additive manufacturing production, Carpenter Additive offers high quality metal powder, a suite of solutions for material traceability, and contract manufacturing from powder to part.

Additive manufacturing of Nitinol allows the fabrication of complex device geometries with pre-designed porosity, homogeneous composition, high density, near net shape, and requires very little to no post-processing. As Nitinol exhibits work hardening in conventional manufacturing processes, additive manufacturing presents unique opportunities in the production of medical devices.

Browse our technical library of resources, including; white papers, product brochures, technical datasheets, webinars, and more.