As we explored in our previous blog, the challenges in powder handling have escalated with the increased throughput of additive manufacturing machines. Today, we delve into the innovative solution presented by Carpenter Additive – the newly-developed Hoppers, available in 250L and 500L variants.

The evolution of additive manufacturing brought about an unprecedented demand for efficiency and scale. However, traditional powder handling methods struggled to keep up, leading to contamination risks, operator exposure, and inefficiencies in the production process.

Recognizing the need for a transformative solution, Carpenter Additive designed and developed our next generation of Hoppers. These Hoppers, available in 250L and 500L volumes, mark a significant leap in addressing the challenges posed by the ever-increasing demand for powder in additive manufacturing.

Design and Features of the Hoppers

The heart of these Hoppers lies in their robust design. A fully welded structure ensures durability and strength, with a minimum Factor of Safety (FoS) of 2:1. This design not only guarantees safety but also longevity in handling the stresses of transportation and production.

Carpenter Additive prioritizes material quality. The Hoppers are crafted from 304L stainless steel, providing a strong, easily cleaned structure with minimal risk of corrosion. The internal polishing, radii, and slope angle enhance flowability, maintaining the cleanliness critical for powder quality.

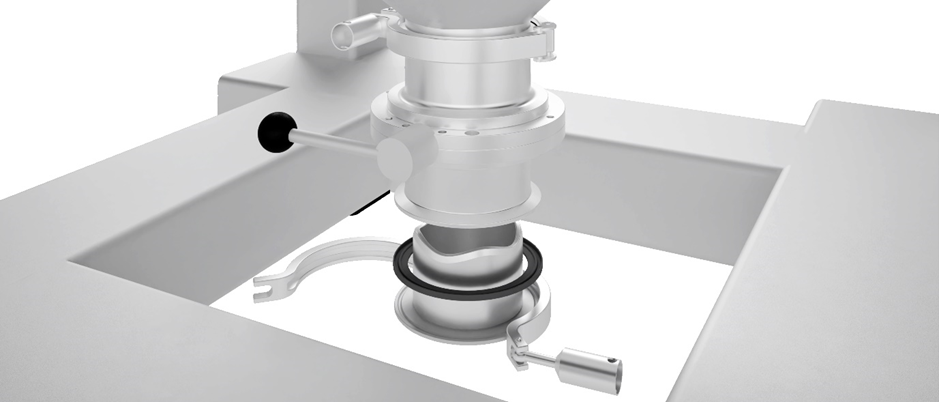

Image 1: The Hopper Deconstructed

Safety Features and Accessibility

Loading and unloading the Hoppers is made secure and straightforward with positively locking handles. This feature minimizes the risk of accidental openings, ensuring a controlled environment crucial for safe powder handling.

Accessibility is key in the design of the Hoppers. Human-readable instruments enhance ease of use, and interchangeable components with standard sanitary fittings streamline maintenance, contributing to the Hoppers' user-friendly nature.

Safety is paramount in additive manufacturing. The Hoppers incorporate a top-side valve to maintain an inert atmosphere, preserving powder quality during processes and connections to ancillary equipment.

Ensuring safety during transit, Carpenter Additive introduces the patented Valve Blocker. This additional layer of safety prevents unintentional discharge of the vessel during transportation, adding a third factor of safety. Furthermore, our patented safety blank serves as an essential safety feature. Positioned atop the upper valve, it prevents the cap from being ejected from the vessel when opening a pressurized hopper, significantly enhancing operator safety.

Image 2: The Patented Valve Blocker

Image 3: The Patented Safety Blank

Transportation Capability

Carpenter Additive’s Next-Gen Hoppers are equipped to handle powder transportation efficiently. With a carrying capacity of up to two metric tons, the hopper ensures mobility through novel fabrication techniques. Its 4-way access allows flexible forklift, pedestrian truck, and pallet truck options, supporting efficient logistics around the production floor. Additionally, built-in lift points support easy crane-handling on site, further enhancing its versatility in various manufacturing environments. This feature underscores our commitment to providing a comprehensive solution that meets the diverse needs of additive manufacturing operations.

Revolutionizing Powder Handling: Challenges and Solutions

Carpenter Additive's Next-Gen Hoppers not only meet but exceed the demands of modern additive manufacturing. With a focus on design and safety, these Hoppers provide a production-ready solution that elevates the efficiency, safety, and quality of powder handling. Stay tuned as we continue to explore the comprehensive features and industry impact of these ground-breaking solutions in our upcoming blogs.