THE HOPPER

HAS LANDED

Carpenter Additive’s sustainable metal hopper for production-scale additive manufacturing delivers a bulk supply of the industry’s best metal powders.

Your full-scale AM revolution starts now

Carpenter Additive is the world’s leading supplier of metal powders optimized for AM — and the first AM-focused materials company to engineer a sustainable, production-ready powder delivery solution. Our next-generation Hopper gives you the high-capacity supply of high-quality powder you need in an easy-to-transport, easy-to-store form.

- Think big: Up to 2 metric tons of powder per Hopper

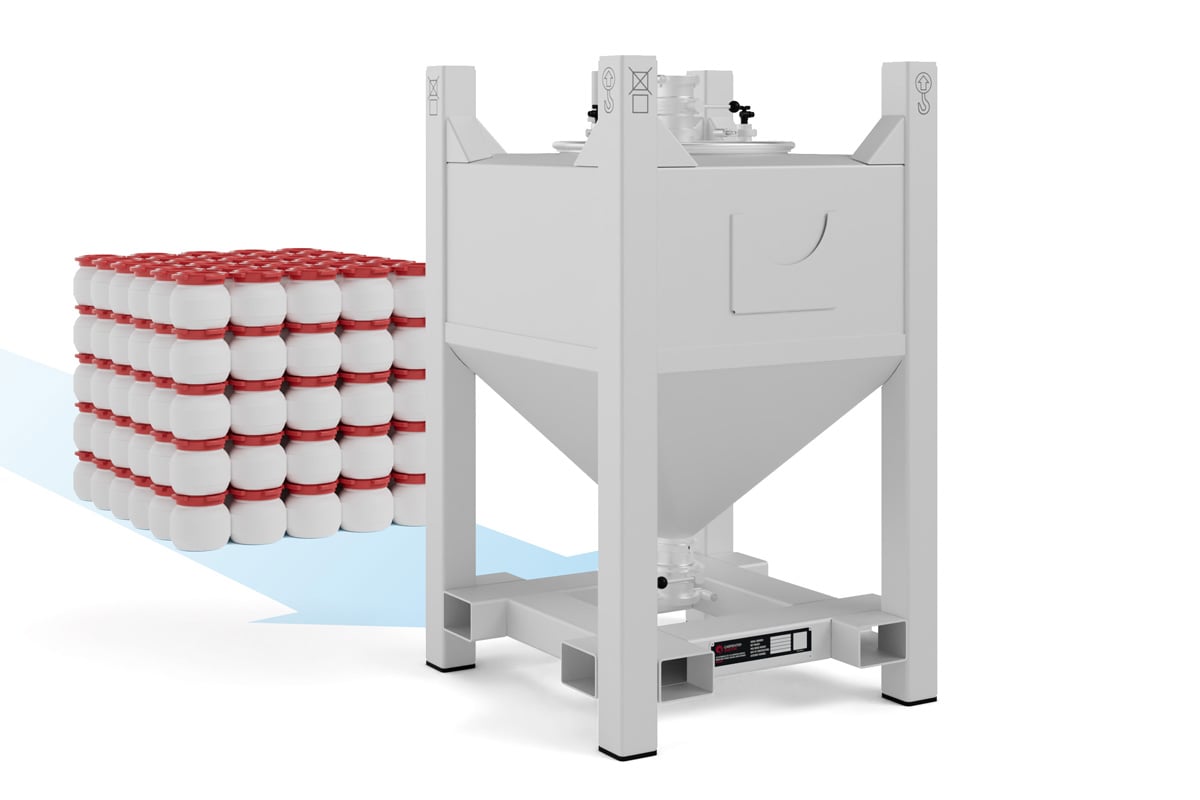

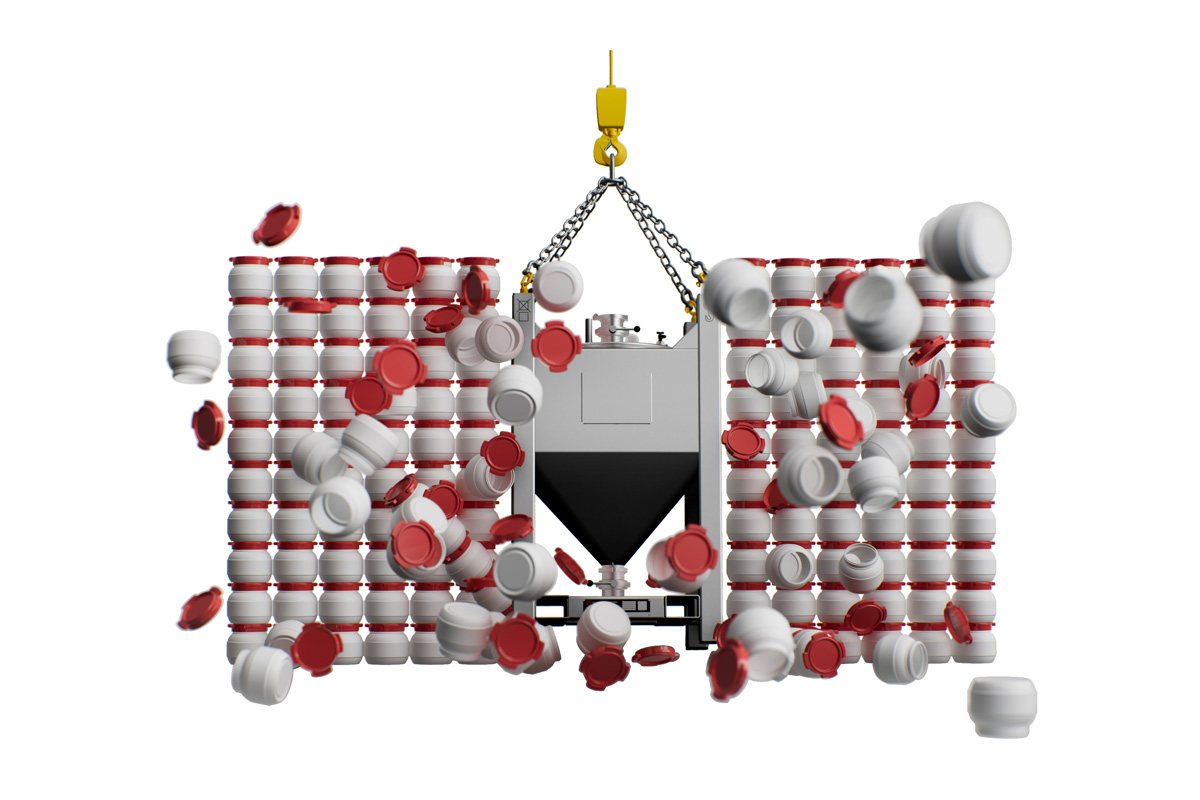

- Eliminate waste: One Hopper replaces 100+ non-recyclable plastic bottles

- Lock down safety and quality: Minimize operator exposure and contamination while optimizing operational efficiency and traceability

Production at volume

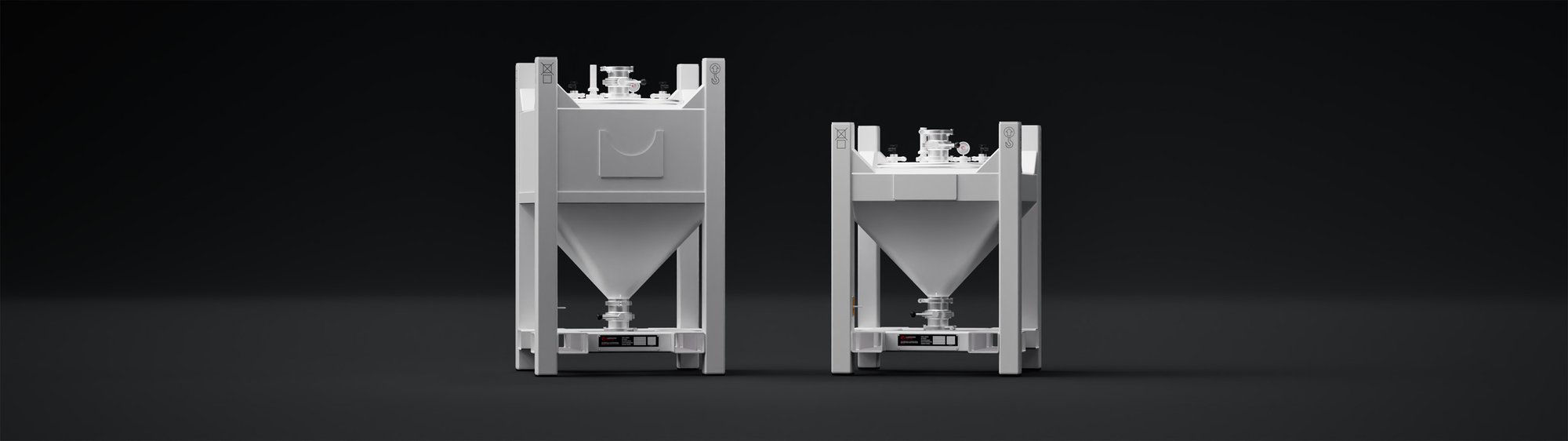

The Hopper is a high-strength stainless steel structure engineered for high-volume AM applications. Select the size that best fits your operation.

Hopper 500 L |

|

Max. fill 2000 kg / 4409 lb |

|

Size 915 x 1535 x 915 mm |

Hopper 250 L |

|

Max. fill 1000 kg / 2204 lb |

|

Size 915 x 1220 x 915 mm |

Built to perform

The Carpenter Additive Hopper provides a closed-loop powder solution, from the point of atomization to loading your AM machines. Our industry-best metal powder is transported and stored under inert conditions, minimizing the risks of operator exposure and material contamination. Each Hopper is alloy-specific and clearly labeled for easy traceability.

- Push-fit connection points to maintain inert atmosphere

- Valves engineered to prevent powder escape

- Patented valve blocker to keep powder inside during transport

- Rugged identification and serialization plate

Built to move

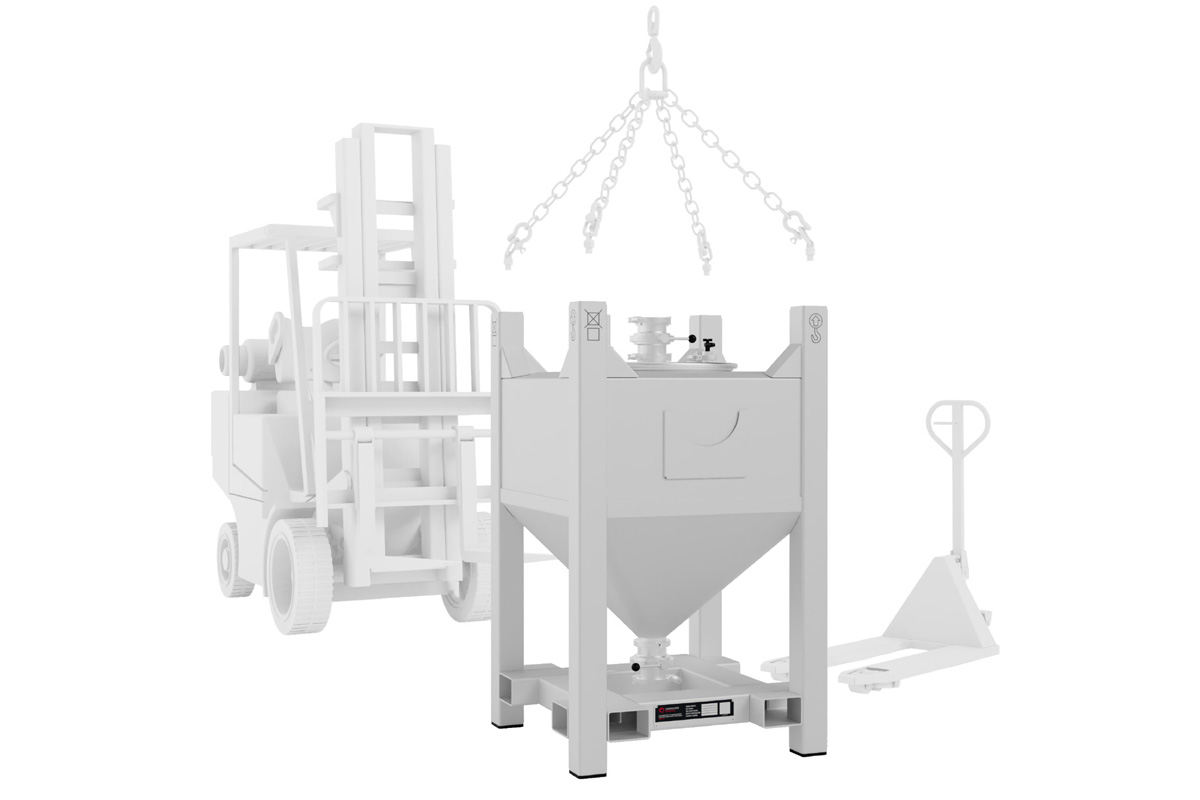

The Hopper offers multi-position access for hand trucks, forklifts, and cranes.

Built to sustain

Filling a high-volume machine with small containers of powder is beyond inefficient — it’s wasteful. Easy to use and easy to clean, the Hopper is a reusable, recyclable powder supply solution. One 500 L Hopper replaces more than 100 non-recyclable plastic bottles. And Carpenter Additive plants a tree for every Hopper purchased.

The Hopper can help you achieve both your production-scale AM and sustainability goals.

PREMIUM METAL POWDER FOR 3D PRINTING

The powder to power at-scale additive manufacturing is in the Hopper. Turn to Carpenter Additive’s broad portfolio of high-performance alloys.

The Carpenter Additive Hopper is the most advanced high-volume AM powder container on the market today.