We manufacture performance materials, and combine these high-quality powders with our additive manufacturing expertise to improve patient outcomes.

Carpenter Additive’s specialty alloys, stainless steels, and titanium materials have been trusted by the healthcare industry for decades. Whether 17-4 PH for medical instrumentation, Nitinol for shape memory properties in medical devices, or Grade 23+ Titanium for high-strength implants, Carpenter Additive has a portfolio of materials to accelerate product development that meet the extremely stringent composition, fabrication, and functional standards for biomedical equipment.

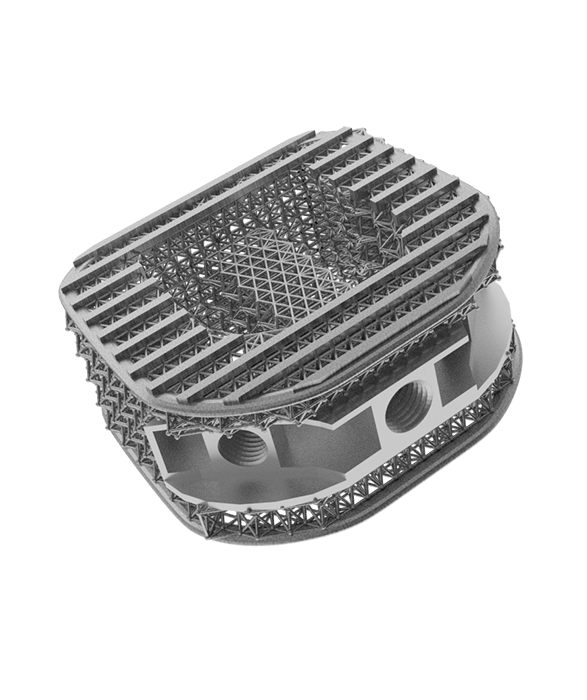

Medical implants that take advantage of AM for complex component design, efficient control of porous morphology, weight, and adoption of suitable biocompatible alloys. Additively manufactured interbody cages allow for superior osseointegration, improving patient outcomes.

Orthopedic implants, such as hip and tibial knee components, fabricated by AM take advantage of design flexibility and efficient control of porous morphology, enabling superior osseointegration.

Customers call on us when they need to rethink the boundaries of specialty alloys or how our existing top-performance materials can solve new design challenges. We foster long-term relationships to support risk-averse innovation and explore advanced product applications together.

Browse our growing library of resources including case studies, product brochures, technical data sheets, product selection guides and more.