Related Resources

Browse our technical library of resources, inlcuding: white papers, product brochures, technical datasheets, webinars, and more.

.png)

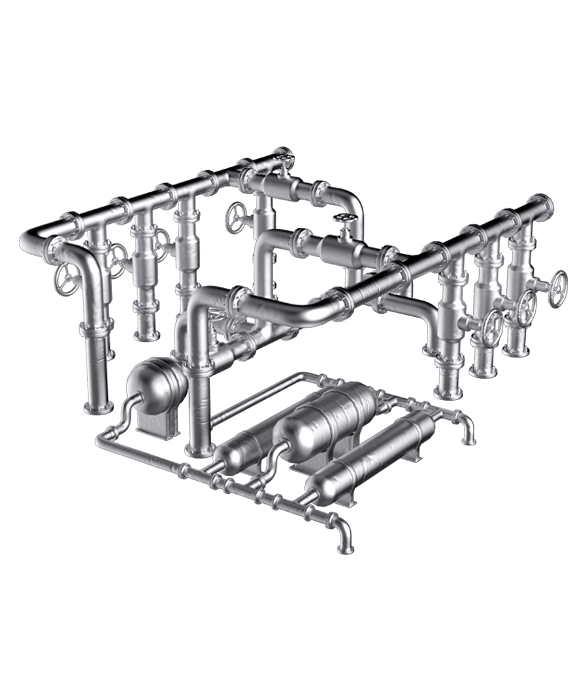

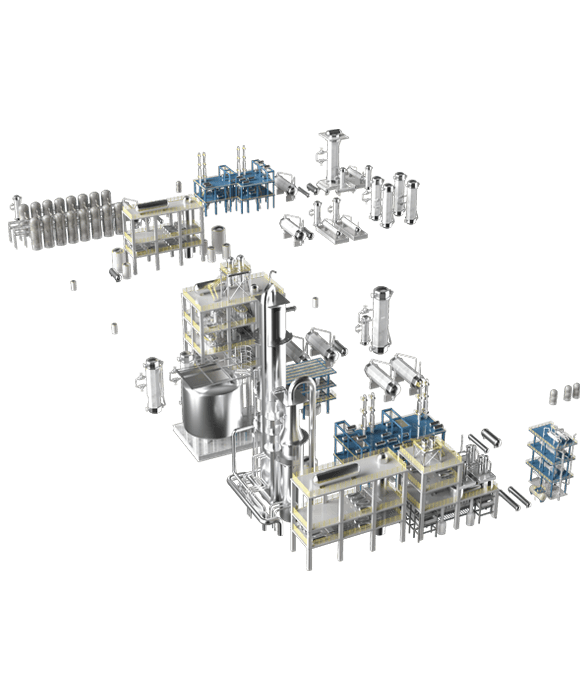

Additive manufacturing allows the geometric freedom to engineer unique designs of the future, incorporating cooling channels or reducing assemblies. Alloys used in industrial applications are continually subjected to varying conditions in harsh, often highly, corrosive environments with pressure changes and temperature fluctuations.

The metallurgical experts at Carpenter Additive offer over 130 years of material expertise to understand an application’s unique requirements, developing solutions and support for customers in the industrial markets.

We supply American made materials for critical applications. Our diverse portfolio of materials can meet exacting standards, ensure safety and dependability while lowering the project cost.

To ensure maximum performance at increased temperatures or during heat load fluctuation, our range of low-carbon hot work steels provide the necessary strength and hardness for effective processes.

Avoid expensive downtime and capital expenses with a selection of materials from a diverse portfolio to meet any requirement.

Customers call on us when they need to rethink the boundaries of specialty alloys or how our existing top-performance materials can solve new design challenges. We foster long-term relationships to support risk-adverse innovation and explore advanced product applications together

Customers call on us when they need to rethink the boundaries of specialty alloys

Browse our technical library of resources, inlcuding: white papers, product brochures, technical datasheets, webinars, and more.