Applicable specifications: AMS7008

Associated specifications: UNS N06002, AMS5536, AMS5754, AMS5798, ASTM B572

Single figures are nominal except where noted.

| Nickel |

| Molybdenum |

| Aluminum |

| Silicon |

| Oxygen |

| Sulfur |

| Balance |

| 8.0–10.0 % |

| 0.50 % |

| 0.20 % |

| 0.10 % |

| 0.030 % |

| Chromium |

| Cobalt |

| Copper |

| Titanium |

| Phosphorus |

| Boron |

| 20.5–23.0 % |

| 1.00–2.50% |

| 0.50 % |

| 0.150 % |

| 0.040 % |

| 0.010 % |

| Iron |

| Tungsten |

| Manganese |

| Carbon |

| Nitrogen |

| Hydrogen |

| 17.0–20.0 % |

| 0.20–1.00 % |

| 0.50 % |

| 0.10 % |

| 0.030 % |

| 0.005 % |

PowderRange® X is a solid solution strengthened nickelchromium- iron base superalloy. It is not considered precipitation hardenable and achieves optimum material properties through solution treatments. It possesses high strength at room and elevated temperatures, and exceptional oxidation and stress corrosion cracking resistance. PowderRange® X displays significantly reduced crack susceptibility compared to the nominal alloy X composition. Its low carbon content and additional solid solution strengthening maximizes its compatibility with laser additive manufacturing processing. Although solution treatment is required for optimum high temperature performance, as-processed PowderRange® X displays mechanical properties equivalent to wrought material at both room and elevated temperatures.

| Part Number | PowderRange® X |

|---|---|

| Application | L-PBF1 |

| Maximum Particle Size | Max 1 wt% > 53 µm2 |

| Minimum Particle Size | Max 10 vol% < 15 µm3 |

| LSD Percentile | D10, D50, D903, reported |

| Atomization | Vacuum Induction Melted, Argon Gas Atomized |

| Apparent Density (G/CM3) | Measured according to ASTM B2124 and reported |

| Hall Flow (S/50G) | Measured according to ASTM B2135 and reported |

1 ASTM/ISO 52900: Laser — Powder Bed Fusion (L-PBF), Electron-Beam Powder Bed Fusion (EB-PBF), Directed Energy Deposition (DED)

2 ASTM B214 Standard Test Method for Sieve Analysis for Metal Powders

3 ASTM B822 Standard Test Method for Particle Size Distribution of Metal Powders and Related Compounds by Light Scattering

4 ASTM B212 Standard Test Method for Apparent Density of Free-Flowing Metal Powders Using the Hall Flowmeter Funnel

5 ASTM B213 Standard Test Method for Flow Rate of Metal Powders Using the Hall Flowmeter Funnel

Testing of powder will fulfill certification requirements to Nadcap Materials Testing and ISO/IEC 17025 Chemical, per relevant ASTM procedures

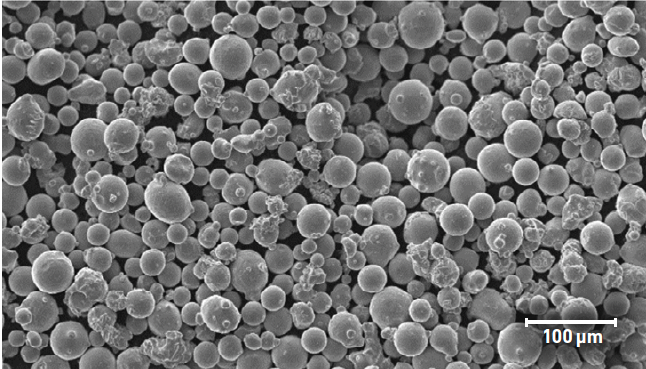

FIGURE 1—SEM IMAGE OF TYPICAL PowderRange X POWDER

ASTM/ISO 52900: LASER-POWDER BED FUSION (L-PBF)

PowderRange X is compatible with all commercially available L-PBF equipment.

To achieve mean, as-built density >99.9%, 30 μm layer thicknesses and Specific Energy ≥ 59 J/mm3 is recommended.

Solution Anneal at 2150°F (1177°C) for 1 hour. To provide an adequate quench after solution treating, it is necessary to cool below 1000°F (540°C) rapidly enough to prevent precipitation in the intermediate temperature range. For thin geometries, rapid air cooling suffices. For heavier sections not subject to cracking, oil or water quenching is frequently required.

While generally not necessary to age, an aging treatment can be applied at 1400°F (760°C); hold 3 hours; air cool; reheat to 1100°F (595°C); hold 3 hours; cool in air.

Schedules tailored better to the AM process thermal history may be available. Please contact Carpenter Technology for information.

We recommend HIP as standard practice for microstructure homogenization; removal of residual spatter-induced voids, trapped gas porosity in powder and keyhole porosities; as well as to heal any shrinkage-induced micro-cracks in the material.

To achieve up to full density (100%): Process components under inert atmosphere at not less than 14.5ksi (100 MPa) at approximately 2300°F (1260°C); hold at the selected temperature for approximately 240 minutes or more.

Follow with Solution and Age treatment as described above.

To machine PowderRange X, we recommend using single-point tungsten carbide tools.

Increasing the speed and decreasing the feed results in better finishes. Excessive speeds are not recommended because the tools will break down.

A sulfur-base cutting fluid should be used. Ample coolant is suggested. Removal of cutting fluid is necessary before heat treating because the sulfur will offset the surface of the part. A rigid work piece and a rigid tool are necessary for optimum machinability.

ASTM F3055: ADDITIVE MANUFACTURING NICKEL ALLOY (UNS 07718) WITH POWDER BED FUSION

| Condition | Transverse | Longitudinal (Y-Z Plane) | Notes |

|---|---|---|---|

| As-Built |

|

|

Mean densities greater than 99.9% |

| HIP/Sol |

|

|

Mean densities up to 100% |

| As-built, etched6 |

|

|

Clean weld tracks visible |

Sol/Age, etched6 |

|

|

Recrystallized equiaxed grain structure minimizes anisotropy Grain size: ASTM 4.0-5.57 |

| HIP/Sol/H900, etched6 |

|

|

Recrystallized equiaxed grain structure minimizes anisotropy Grain size: ASTM 4.0-4.57 |

6 Etched with oxalic+HCl

7 ASTM E112-13 Standard Test Method for Determining Average Grain Size

8 Average of a minimum of 5 samples taken from across the extents of a build plate in each orientation and for each heat treatment. Testing performed in accordance with ASTM E8/E8M-16a (tensile), ASTM E23-18 (impact energy) and ASTM E18-19 (hardness). Additional data may be available through a wide range of consortia and other collaborations. Please contact Carpenter Additive for additional information.

9 ASTM B572-06 (2016) Mechanical Property Requirements for N06002

10 Carpenter Technology Alloy 680 alloy bar and plate typical values

IMPORTANT NOTE: The following 4-level rating scale (Excellent, Good, Moderate, Restricted) is intended for comparative purposes only and is derived from experiences with wrought product. Additive manufactured material may perform differently; corrosion testing is recommended. Factors that affect corrosion resistance include temperature, concentration, pH, impurities, aeration, velocity, crevices, deposits, metallurgical condition, stress, surface finish, and dissimilar metal contact.

| Nitric Acid | Good |

| Phosphoric Acid | Good |

| Sodium Hydoxide | Good |

| Sea Water | Excellent |

| Humidity | Excellent |

| Sulfuric Acid | Good |

| Acetic Acid | Excellent |

| Salt Spray (NaCl) | Excellent |

| Sour Oil/Gas | Good |

| Company |

| Other Generic Names |

| 3D Systems |

| GE (Concept Laser) |

| EOS |

| DMG Mori (Realizer) |

| Renishaw |

| SLM Solutions |

| Alternative Title |

| Hast X, Alloy X |

| – |

| – |

| NickelAlloy H |

| - |

| - |

| HX |

For additional information,

please contact your nearest sales office:

info@carpenteradditive.com | 610 208 2000

The mechanical and physical properties of any additively-manufactured material are strongly dependent on the processing conditions used to produce the final part. Significantly differing properties can be obtained by utilizing different equipment, different process parameters, different build rates and different geometries. The properties listed are intended as a guide only and should not be used as design data.

The information and data presented herein are typical or average values and are not a guarantee of maximum or minimum values. Applications specifically suggested for material described herein are made solely for the purpose of illustration to enable the reader to make his/her own evaluation and are not intended as warranties, either express or implied, of fitness for these or other purposes. There is no representation that the recipient of this literature will receive updated editions as they become available.

Unless otherwise specified, registered trademarks are property of CRS Holdings Inc., a subsidiary of Carpenter Technology Corporation.