Our expert metallurgists and additive engineers understand the materials that improve aerodynamics, reduce weight to increase fuel efficiency, are heat resistant, as well as those that can provide more strength and functionality.

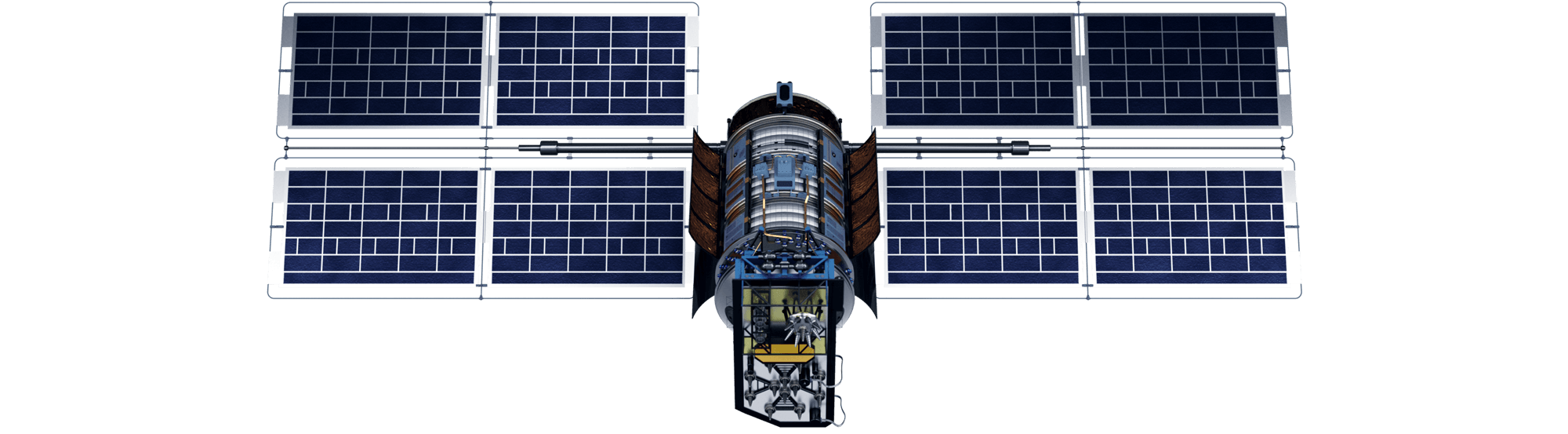

We continue to make advancements in high-quality iron, nickel, cobalt, and titanium-based aerospace alloys to optimize additively manufactured parts. A trusted material supplier to the world’s foremost leaders in the aerospace market, Carpenter Additive aligns material solutions and production expertise with the current and future needs of commercial and defense aviation, manned aircraft, and unmanned systems.

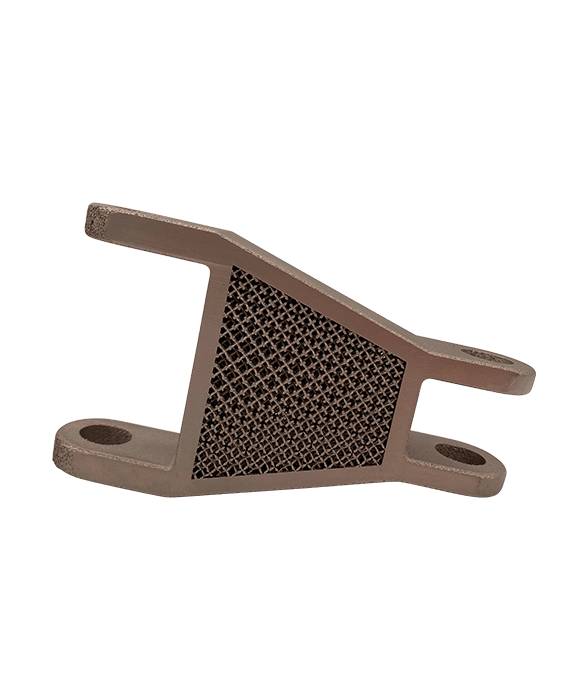

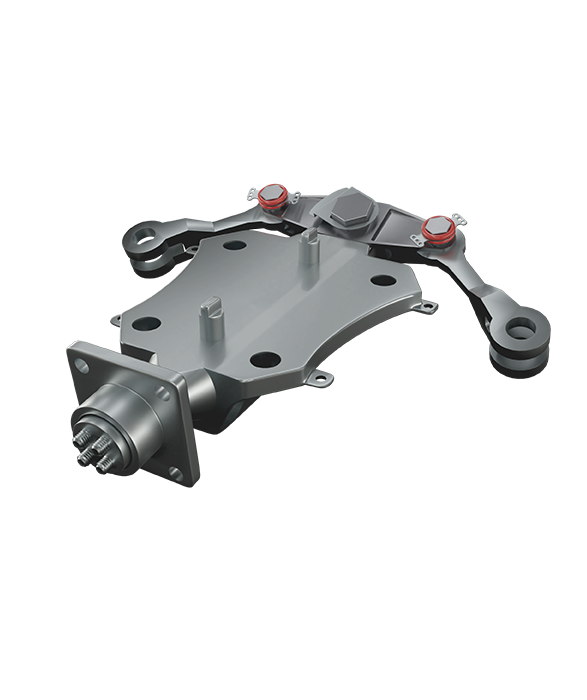

Additively manufactured aerospace brackets are developed to maximize performance while reducing weight through geometry optimization and high-strength materials.

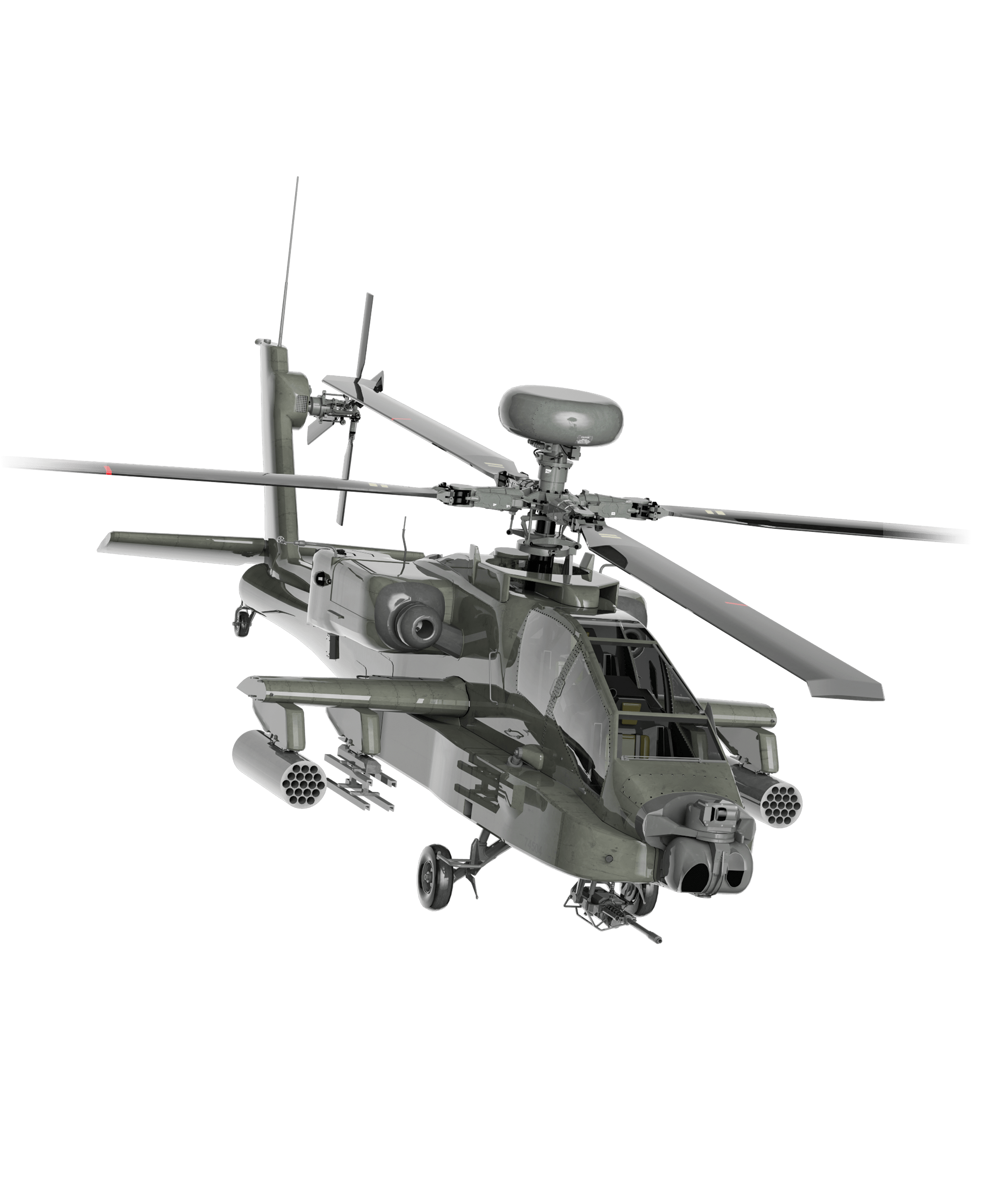

Subjected to salty spray and high-torque, materials on marine helicopters demand the highest performance, reliability, and readiness. We customize material properties to specific applications, delivering high-strength in corrosive environments.

Fasteners add weight. On aircraft, the strength to weight ratio is critical. Meanwhile, quality is essential in no-fail situations that include temperature extremes, high pressures, stress and weight loads, and corrosion.

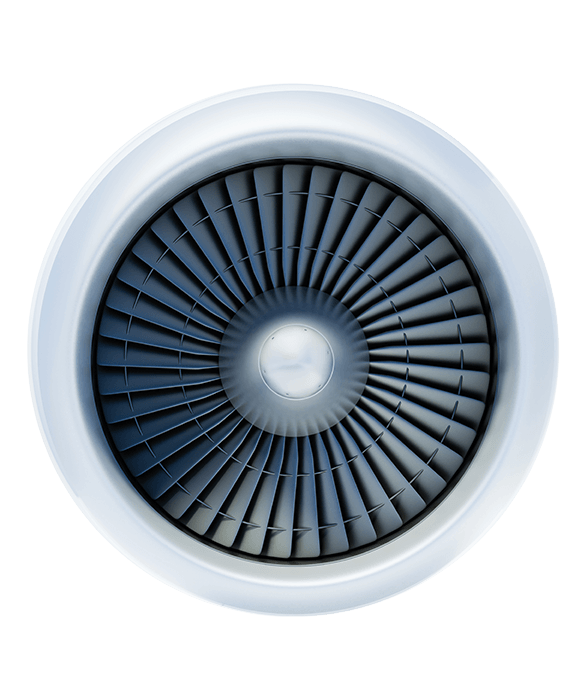

Connects to the wing and transmits the thrust forces generated in extreme environments.

We help develop fatigue-resistant materials for critical applications that maintain stability at high operating temperatures while withstanding high rotational speeds, high-velocity exhaust, and lateral forces without failure.

Customers call on us when they need to rethink the boundaries of specialty alloys or how our existing top-performance materials can solve new design challenges. We foster long-term relationships to support risk-averse innovation and explore advanced product applications together.

Browse our growing library of resources including case studies, product brochures, technical data sheets, product selection guides and more.